The luck of the Irish?

Protranz Eartmoving Ltd

Protanz Earthmovings fleet of trucks and equipment.

First published February 2009

By Simon Vincent

How often do you arrive at a transport yard to be confronted by a large tank bearing the number plates GBH4U? Well if you ever have to visit Protranz Earthmoving, in Christchurch, that is exactly what you are likely to be greeted by – an Abbot FV433 Self-Propelled Gun. Protranz owner, Gerard Daldry, said he had always wanted to own one of these war horses, and when the opportunity arose to purchase one recently, he acted quickly.

An impressive welcome to the Protranz yard.

Aside from owning an ex British Army tank, Gerard owns and operates a small demolition and earthmoving concern on the northern outskirts of Christchurch. Gerard has had a fairly lively career in transport, from starting off shovelling concrete for the Burnett Transport company in Ashburton, to experiencing all the highs and lows of owning his own business.

During his time in business, Gerard has moved from running a single truck, as a side line, to having an operation with thirteen staff. Time and a greater understanding of his business has seen Gerard scale his operation back to five staff, a level he is particularly comfortable with and one that still generates a comfortable return on investment.

Colourful Character

Gerard Daldry

Gerard is one of life’s colourful characters, once met, never forgotten! Gerard is fiercely proud of his Irish Catholic heritage which is highly visible in his nature and some of the mementoes he has. It was many many years ago that we first came across Gerard, when he was driving a R Model Mack tipper for Allied Concrete, based out of their Christchurch yard, and we have gotten on well ever since.

Taking this night shot was enough to arouse the interest of the local constabulary.

At that stage Trengenzas, from Timaru, were still in the Richardson Group fold, and Gerard was down in Timaru working one of the regular fert boat runs, delivering raw materials for the Ravensdown fert works out at Seadown.

Young and Keen

Young and keen, we were anxious to get photos of the truck for our records, and even arranged to do a night shot with Gerard’s truck at Tregenza’s Washdyke yard. This was all going well until the local constabulary arrived wanting to know exactly what we were doing, as a few days earlier some of the trucks had been broken in to and radios stolen. (Some of the locals had seen us around the yard and reported us.) A good bit of quick talking convinced the ‘Bobbies’ we were legit and they headed back off into the night as we continued our work.

Gerard has been around trucks almost all his life. Both his father and Uncle drove for the well known ‘Mid Canterbury Transport’ company based out of Rakaia. Some of Gerard’s earliest memories of truck driving were out with his Uncle steering (holding the truck in a straight line might be more to the point) as they would load bagged grain or hay bales.

Regular jobs

These were regular jobs, with side mounted hay lifts attached to the truck or the old rear mounted Briggs and Stratton powered bag lifter. Gerard would steer the truck, usually a TK Bedford, or later a D Series Ford, straight along the paddock rows. Come the end of the row, the driver would jump down and ‘help’ him turn the truck around before commencing on the next one.

An example of a Burnetts KM Bedford.

The seed was sown in this young mind and Gerard would bunk school to go out with one of the neighbours in one of Burnett’s Detroit powered TM Bedfords, and later a brand new International 3070 eight wheeler, to do stock. Gerard wasn’t inclined to the school life, and at the age of fourteen he left.

Farm Worker

Initially Gerard worked on a farm, and when this job came to an end the cockie rung Burnetts and arranged for Gerard to work for them. Not being old enough to gain a Heavy Transport Licence Gerard was set to work in the concrete factory and began ‘shovelling concrete’ for the posts, tanks and other concrete products.

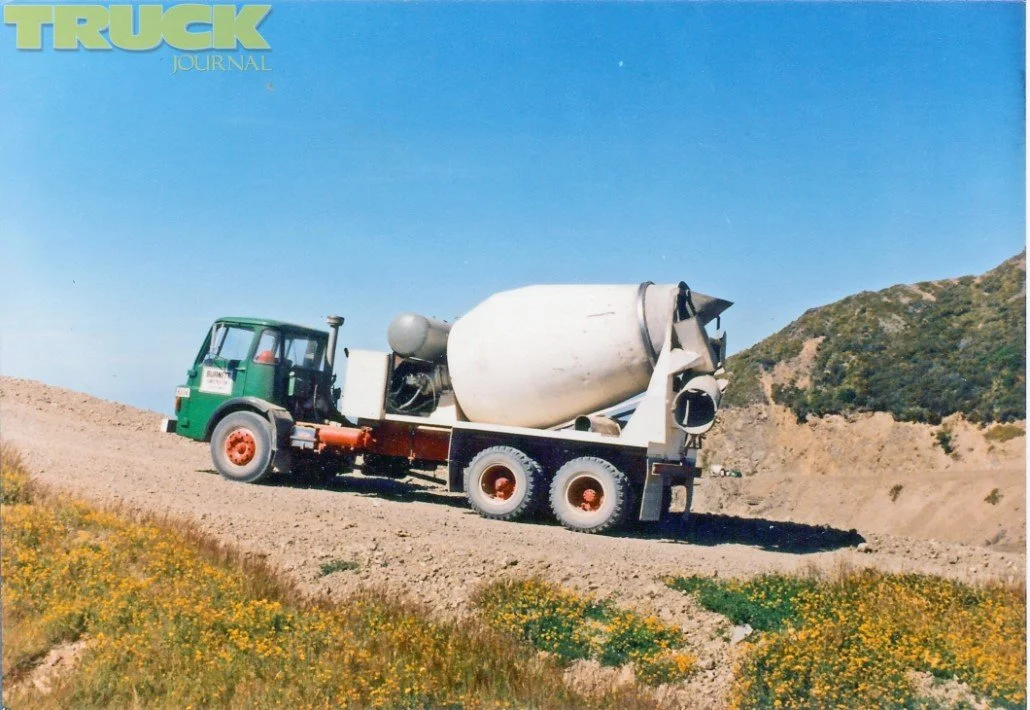

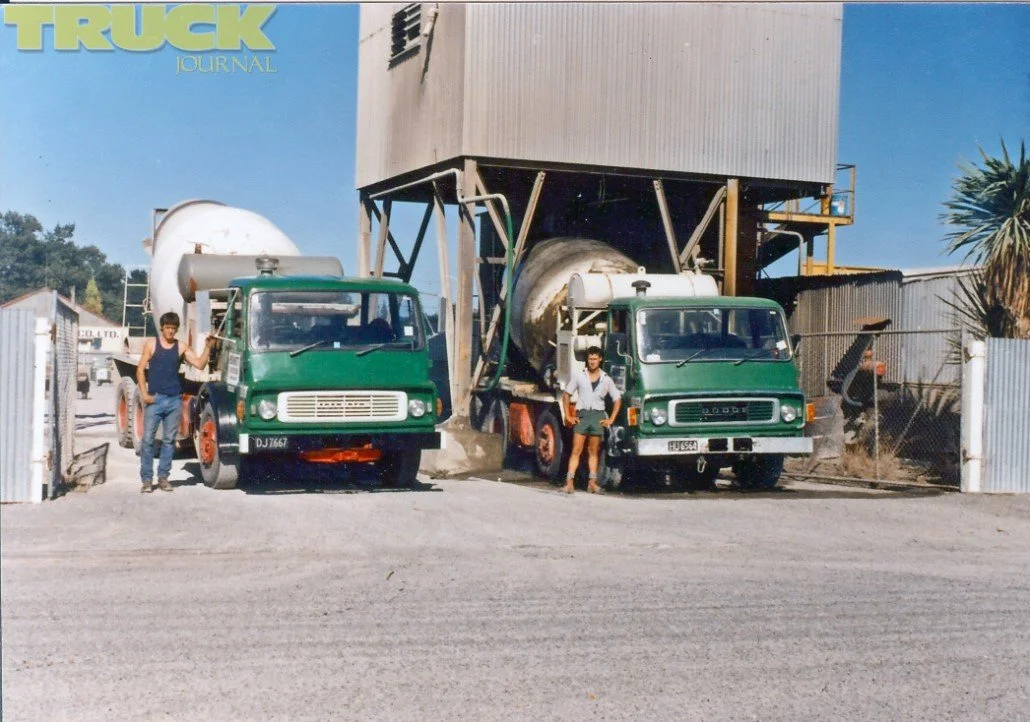

As soon as he turned eighteen Gerard was straight into a truck. His first was a V8 Perkins powered Commer (No. 539) concrete mixer and his second a TS3 powered Commer which failed to last very long. Next came a Dodge, again with a V8 Perkins, and this truck saw Gerard through until he left Burnetts.

As we all remember, trucks weren’t much chop back then. Gerard vividly remembers carting 4m3 of dry mix up to the Mt Hutt Ski Field at Methven. The trip from the yard in Ashburton to the bottom of the ski field took one hour, the trip up the mountain took an hour and a half! But it was the occasion when Gerard (and truck) was ‘lent’ to Christchurch operators Farrier-Waimak Ltd for three weeks that spurred the next change.

To drive a Mack

Farriers were running a number of Mack concrete mixers, and the idea of driving a Mack seemed pretty good to Gerard. On his return from Christchurch Gerard handed in his notice. There is quite a funny aside to his departure. Having agreed to finish on a Friday, he was roped into working the Saturday doing border dyke gates – a real pain of a job!

None the less come Saturday and it was out to the job with an off-sider. This would help as he wouldn’t have to jump out every few metres to drop a barrow full of concrete and move forward again. Whilst traversing one of the border dykes, the twist in the chassis snapped the exhaust brackets which shorted out the starter motor and set the truck on fire. Once extinguished, the truck was towed back to the yard to serve as an inglorious finish to Gerard’s Burnett’s era.

Moving to Christchurch

Once in Christchurch Gerard got put on an International ACCO, with a Detroit Fuel Pincer and Allison Auto concrete mixer, before transferring to work as the hose man on the Mack MC concrete pump. After a couple of months the pump operator moved back into the main fleet and Gerard took over as the driver operator for the next eighteen months. His most vivid memory of the Mack is the top road speed of 88km/h accompanied by a huge whine from the transfer case in the drive line – they could never find the cause.

From here Gerard moved to the R Model tipper hauling aggregates around Christchurch to supply the concrete plants, in addition to outside work such as the fert boats etc.

Off to Wellington

In 1989 Capital Concrete was in its infancy and Gerard took an ex Freight Haulage R Model up to take over the aggregate delivery to the two Wellington plants in Tawa and Landfill Road. The Tawa plant was extremely tight and the previous contractor had used a tractor unit and semis to stock up the plant, bringing in a truck and trailer was a bold move.

By the age of 24 Gerard was behind the truck of his dreams – a V8 Mack Superliner with 500hp – he was in heaven. To begin with, the Superliner was a tractor and semi but it was soon converted to a truck and trailer. Initially Gerard towed a two axle trailer, then a three axle was tried and found to work perfectly.

A lesson learned

Gerard found that by digging out just one metre from the bank behind the plant, trucks and trailers could be comfortably manoeuvred – a lesson not lost on company owner Bill Richardson. Gerard said that Bill would always go and look for himself rather than rely on the word of others after that.

Times were tight when Gerard arrived in Wellington but as the economy picked up, so did the amount of work.

More trucks were put into work to cope with the increased need for gravel and Gerard eventually found himself at the business end of a desk. Gerard found the walls closing in on him and within two weeks he was behind the wheel of a CH Mack and still directing all the traffic around Wellington.

Learning Experience

Working for Bill Richardson was a huge learning experience, according to Gerard, much of what he needed to know, he learned on the job at Allied. Bill must have been blessed with great deal of foresight – when Gerard wanted to do an OE in 1994 he was allowed 16 months off with his job still being available when he returned.

Gerard used this to great effect, travelling to work for British Company ‘Boughey Distribution’ of Cheshire driving an E10 325 hp ERF all over England and right into Europe. One load was particularly memorable – a full load of New Zealand Milk powder.

Work kept increasing at the Wellington operation and was getting out of hand. Regal Haulage had been providing some coverage but Gerard could see the need for a part time relief truck. He had previously toyed with the idea of purchasing a truck and running it himself. This would be a bold move, considering he was working for Allied and there could easily be a conflict of interest with his existing position.

First truck

Gerard did not wish to rock to boat, but he really wanted to have his own truck. Action was called for and Bill Richardson was phoned to discuss the proposal. Bill gave the go ahead with a single piece of advice –‘If you feel there might be a conflict, examine your conscience’. This profound bit of advice provided Gerard with a sound platform to launch his career in trucking and one he remembers well to this day.

Gerard was now a truck owner, his first truck being a smartly turned out deep green International S Line tipper with four axle trailer. He would run this truck as a sideline, handling overflow work for Allied as well as sourcing additional extra work from outside companies.

Return to the ‘Mainland’

Things were going well but the desire to move back to the ‘Mainland’ grew. Close friend and mentor, Ted Wills from TWT in Christchurch, had more than enough work for another truck. Gerard packed up the S Line and shifted south to Christchurch to work as a subcontractor to TWT in 1999. Work was plentiful and Gerard was able to update the S Line with a CH Mack with a high sided alloy tub.

A change in direction in 2002 meant the deep green livery was revived and Gerard returned to the types of work he was most familiar with – aggregates and similar construction based products.

First Growth

When he found a small Christchurch bobcat company that was struggling, Gerard saw a prime opportunity to take over the company’s work and clients. Protranz took over the trucks and machinery and quickly found itself growing and expanding. In addition to aggregate haulage, demolition and earthworks were quickly added to the expanding portfolio.

Business was brisk and over a period of several years staff numbers grew, peaking at thirteen. Gerard found that even with so many staff, he wasn’t making any more money, just working harder with little to show for the extra effort. He said, “Some of the guys were just there to collect their pay.” Getting good reliable and dedicated staff proved to be very difficult.

Settling at five

Gerard learned from this experience and has since dropped his staff right back to five workers, an office lady and himself. At this level he is very comfortable with the calibre of the people, and with the volume of work they are able to handle. His current compliment of men is handpicked and his top operators have shares in the company ensuring not only greater loyalty from them but also the opportunity to share some of the rewards with his most dedicated workers.

He confidently speaks about how customers are now ringing and asking for his men by name to complete specialised tasks. Rhys is an expert with excavators, he is in demand for his ability to break out hill sites, prepare footings and spread floors in preparation for concreting. Gerard reckons Vaughan would be one of the best bobcat operators in the country and is the company’s specialist when it comes to demolition work. Then there is Brian who is a wiz with site levels.

ACC workers

One of the most interesting experiences Gerard has had has been working with the local ACC branch with workers returning to work under one of ACC’s programmes. Gerard has found this an ideal way to assess and retain motivated men and he has been able to retain two ACC clients as full time staff. Both Rick and Andy have been employed after passing through ACC work schemes.

Pushing up gypsum in a massive warehouse.

And the men are well looked after at all times of the year. When we arrived during the first working week of January, Vaughan, Rhys and Brian were all in attendance, even though work wasn’t really due to get started till the following week. The time was passed by making sure that all the trucks and machinery were up to scratch and that any jobs needing done around the yard were finished.

Looking after the men

Gerard is so serious about looking after his staff that last year he closed down the whole operation for a week and flew his whole team over to Australia to attend the Melbourne truck show and an associated visit to the Kenworth Factory. (Being staunch Mack men, the poor Kenworth salesman copped a fair share of good humoured ribbing on the bus rides.)

Gerard is keen to keep good staff and is happy to go the extra mile to make them feel appreciated.

But business hasn’t been all beer and skittles, there have been some very trying times along the way and Gerard is not shy in admitting to having had to learn along the way. With only partial high school training, he said that there had been some hard lessons learned, and sometimes they were very costly ones.

A celebration

Two of his new Nissans were extensively damaged before they reached their first birthdays, so when the third new Nissan survived its first year, there was much celebration in the yard. One truck was a write off when it rolled off a bridge, whilst the second had the cab clean knocked off when on a job. Having trucks off the road is not only very stressful, Gerard points out, but also can be very costly while repairs are carried out.

Additionally, Gerard has learned not to work for ‘idiots’ nor for those who are difficult or slow payers. Time and an established client base allow him to be choosy about whom they will or will not work for. As he said, “We don’t work for deadwood.” For his biggest customers, deals worth hundreds of thousand can still be ‘done on a hand shake,’ and payment arrives on the twentieth of the month following. Of others he says, “You don’t start without long written contracts.”

A point to note, Gerard states that everything was going fine in the building industry until the first mention of a recession, and then he says a number of builders suddenly all went out of business. However, Gerard still works with a number of substantial building firms and he said that these companies are still working on new projects and developments.

Buying experience

Gerard has learned what to buy and what not to buy over the years. He currently purchases Hyundai excavators from Porters, not because they are the best machines available, but because of the unbeatable service and backup the Porter organisation can provide. Porters deliver an outstanding level of service, have backup machines if needed, and have every attachment under the sun available to help out if required.

And with the trucks there is a similar level of loyalty. Whilst Gerard would love to run some of the top European marques, practicality, reliability, and total value for money dictate a different purchasing regime.

These older model truck attracted more thean their fair share of attention form the CVIU.

When they took over the other earthmoving operation, they inherited a couple of older CXH Isuzu, which seemed to attract a lot of attention from the CVIU, since they have switched to the new trucks this attention has diminished significantly.

Nissans the best

Nissan has proved to be the best, and the company’s three main trucks are from this Japanese stable. The oldest is a 400hp tractor unit, brought second hand with about 500,000kms on the clock, the truck needed considerable work to bring it up to Protranz standard.

Versatility is key to success in a small operation as is cooperating with other like minded operators. Here is one of the Nissans loading grain on a farm with a TWT semi trailer.

Next is a 400hp eight wheeler tipper, and the latest is a smart 440hp six wheel tipper with super singles on the front. Initially this truck ran standard singles but a trial of several tyre sizes and profiles resulted in the switch to the large rubber. Gerard was swayed into the decision by looking at other operators running similar trucks (like Sollys from the Golden Bay) and figured that if top operators would spec them, maybe he should try them out.

Super singles

The end result is that the super singles, coupled with a seven tonne front axle rating, have delivered significant savings. The tyres themselves deliver almost twice the mileage of standard 11Rs, whilst the extra axle loading affords a small amount of comfort when loading – even with onboard scales. In the past loaders had much smaller buckets, which proved excellent for distributing the load as desired. The introduction of larger machines may mean fewer trips to the pile, but placing the load in the deck becomes far more critical.

Mileages aren’t high for the fleet either, with the average being about 30,000km per annum. Maintenance can be higher than for on highway operations, with the need to halve some servicing intervals, but careful maintenance by their chosen contractor has allowed the company to regularly achieve clean sheet COFs – very important given the upcoming ORS.

Playing with GPS

Whilst the fleet is fitted with GPS, the saving in off road kms claims is not sufficient to cover the cost of running the GPS units. However Gerard is philosophical about the units, he says they were put in on the understanding that they would cover their own cost. While they don’t cover costs they do provide a level of visibility and proof of time on site (not that they have had to use this feature). But he sums up saying, ‘basically, they make you more professional’.

Size isn’t everything, as Gerard Daldry has found, lessons learned along the way have proved to him that having a large staff is not necessarily the most economic option, and Gerard now has found the optimum size for his operation.

Typical for industry

Like so many in the trucking game, Gerard did not have a long school career, yet working hands on has helped him build a successful business. As he pointed out, none of his staff have any great education, yet all have found a valuable path in life, often doing exactly what it is they wanted to do. In this game, skill, co-ordination and ability rate far higher than academic qualifications.

Gerard’s early years working for the Richardson Group taught him some significant values and skills which have assisted in honing his business skills. And, like the rest of us, Gerard has learned from his mistakes, quickly adapting to changing circumstances to succeed.

Today the Protranz operation falls into the well run small business/family operation category. The gear is first class, the staff settled and productive, and a solid client base helps ensure sufficient ongoing work. Whilst we keep getting told the economy is about to collapse and the sky might fall by the general media, the reality is that work keeps coming and trucks and diggers keep working.

Photos: Simon And Alex Vincent, Andrew Geddes, the Gerard Daldry collection, the late Stu Barnes collection.

ABBOT FV433 Self-Propelled Gun

Not too many people keep an historical army field gun as a show piece.

Whilst the Abbot may look like a tank, it is not a tank, but a self propelled artillery piece, with a 105mm field gun, used to replace towed artillery pieces. Developed between 1958 and 1960, the Abbot was used in front line British Army service until the mid 1990s.

The Abbot has a maximum range of 15 km with the Mk 1 ammunition, and 17.4 km with the later Mk 2 round. Maximum rate of fire was 6 - 8 rounds per minute. The gun was able to be elevated upwards to 70 degrees and depressed to 5 degrees below horizontal, and the turret could transverse through 360 degrees which proved sufficient to engage enemy Armoured Fighting Vehicles if necessary.

Rolls Royce

This mighty beast is powered by a K60 Mk 4G Rolls Royce horizontally opposed (like a Rootes Group TS3 used in Commers) multi fuel engine coupled to a 6 stage Allison auto. It develops up to 240 bhp @ 3750 rpm. Being multi fuelled it can run on petrol, diesel, kerosene, jet fuel, or any mixture of these. The Abbot rides on five torsion bar wheel sets and is able to travel at about 47kph and has a range of 480 kilometres.

The Abbot is able to swim through water, having a flotation screen around the hull which is raised to provide buoyancy. The moving action of the tracks is sufficient to drive it forward at about 3 knots.

The Abbot is 5.8m long, 2.6m wide and 2.5m high, weighing 16.56 tonnes when empty. A crew of four manned the gun and, in the event of nuclear or chemical warfare, it had sufficient capacity to protect the crew for five days.

Importing the gun

The multi fuel Rolls Royce engine isn’t necessarily the most clean burning…

Gerard was able to import his machine from England, which is not as easy as it might sound. Anyone looking to import something similar would have to undergo a significant security check and have the right contacts overseas to secure one. The gun has been disabled to prevent any further use.

The Abbot is fully road legal in New Zealand and can be found scooting about from time to time. Fueling the machine may be easier than meets the eye as the shandys of diesel/petrol mixes that motorists mistakenly put into their fuel tanks is ideal for running the Abbot.

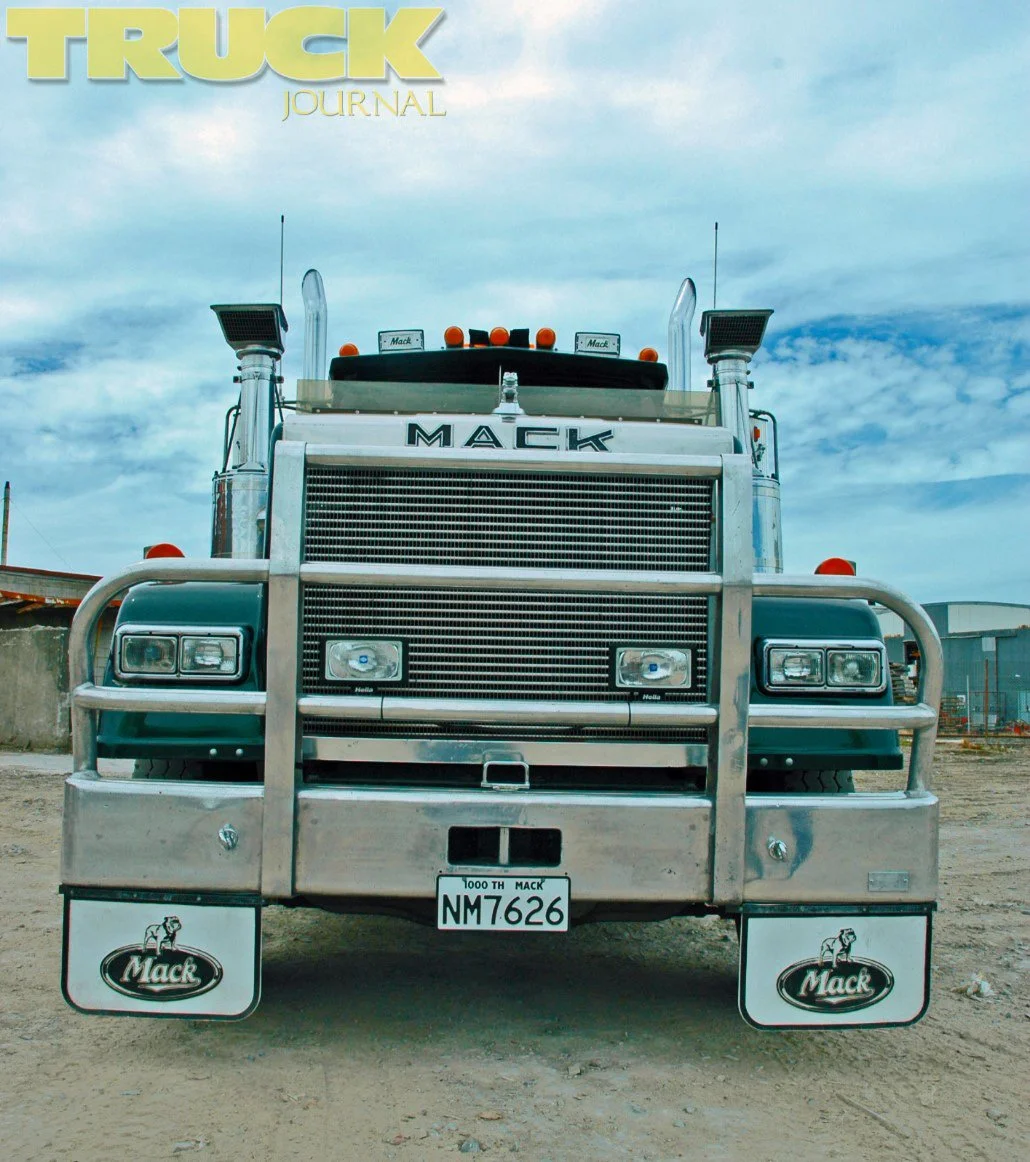

The 1000th Mack

Gerard has had this very special Superliner since 2004.

After much pomp and ceremony, at Palmerston North in 1987, the Super-Lliner was handed over to Bill Gilbert at Southern Transport who put most of the 750,000kms on the clock, pulling logs around Southland. From there it was sold to Roadex in Alexandra who added another 200,000 with either a tanker semi or demountable tip deck.

Jumping on a plane

When Gerard first heard the truck was for sale, he hopped on a plane to Queenstown, and shot over to Alexandra to buy it – regardless of how it looked. We were fortunate enough to feature the Super-Liner in May of 2005 and to have a quick drive of this iconic truck.

There’s no missing the destinctive lines of a Mack Super-Liner.

Since then the Super-Liner has undergone a major rebuild. To maintain originality, the gearbox was rebuilt rather than having a re-Mack fitted (even though it cost considerably more). When she was sent out for painting, only a cab shell and bare chassis left the yard.

Better than new

Having seen the finished product, the 1000th Mack looks better than new, even though it has done in excess of 1 million km. Considerable effort has gone into maintaining its originality. To ensure that only the select few get a chance behind the wheel, Gerard has stripped off the hydraulics and now keeps the Mack securely locked away.

The unique lines of the impossing bonnet and the power and sound of the Mack E9 V8 engine ensure that the Mack Super-Liner remains a sought after truck even today.

So why does he own it? Because he remembers driving a Super-Liner at age 24 in Wellington. Is it for sale? Definitely not! If the truck was ever to leave Gerard’s possession, there is only one place it will go – the Richardson Collection in Invercargill.